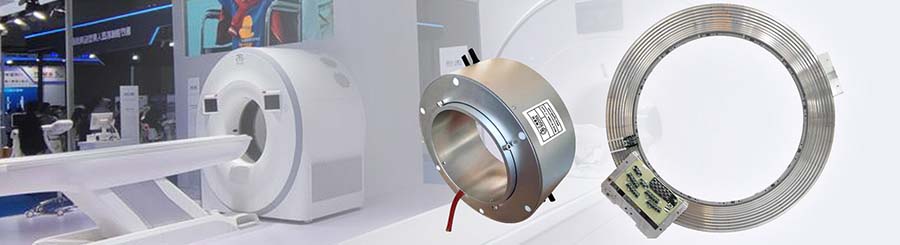

Medical slip ring cases

The medical industry relies on various complex and advanced equipment for diagnostics, treatments, and patient care. Slip rings are essential components in medical devices and equipment due to their ability to transmit power, signals, and data between stationary and rotating parts. Here are some reasons why the medical industry needs slip rings:

Medical Imaging Equipment: Devices like MRI (Magnetic Resonance Imaging) machines and CT (Computed Tomography) scanners require slip rings to transmit power to the rotating components such as gantries and patient beds. These machines generate detailed images of internal body structures, and slip rings ensure uninterrupted power and data transmission during the scanning process.

Surgical Robotics: Robotic surgical systems often have articulated arms that require precise control and mobility. Slip rings enable continuous power and communication between the stationary control console and the robotic arms, allowing surgeons to perform minimally invasive procedures with accuracy.

Endoscopy Systems: Endoscopy equipment uses slender, flexible devices with cameras to visualize internal organs. Slip rings enable the rotation of the camera-equipped endoscope while transmitting real-time video feed and control signals to the external display and control units.

Patient Monitoring Systems: Patient monitoring equipment, such as bedside monitors and telemetry devices, need to monitor vital signs while allowing patient mobility. Slip rings enable the transmission of data from sensors attached to the patient's body to the monitoring equipment without tangling wires.

Radiation Therapy Machines: Slip rings are essential in radiation therapy machines that require precise positioning of radiation sources around the patient. Slip rings facilitate the rotation of the treatment head while transmitting control signals and power to ensure accurate radiation delivery.

Diagnostic Equipment: Various diagnostic tools, such as blood analyzers and centrifuges, require rotation for sample processing. Slip rings enable the transmission of power to the rotating parts and data from sensors for accurate diagnostics.

Laboratory Automation: In automated laboratory systems, where samples move between different stations for analysis, slip rings facilitate the movement of samples and devices while maintaining power and communication connections.

Rehabilitation Equipment: Slip rings are used in rehabilitation equipment such as motorized wheelchairs and robotic exoskeletons. They allow mobility and controlled movement while transmitting power and control signals to the moving components.

Medical Research Instruments: Slip rings are used in various medical research instruments that involve rotating components, such as centrifuges, microscopes, and incubators.

Reduced Contamination Risk: Slip rings eliminate the need for cables that could hinder medical procedures or introduce contamination risks in sterile environments.

3GOTEK TECHNOLOGY

3GOTEK TECHNOLOGY